The bottleneck of insulating glass

What are the methods for reducing heat transfer coefficient of insulating glass(IG)? After using low emissivity coated glass with lower hemispherical emissivity, increasing the number of layers of LOWE glass, filling with inert gas (argon or expensive krypton gas), or appropriately increasing the thickness of the intermediate layer (not exceeding 16mm).

Then, we will find that we have encountered a bottleneck. The way to break through is to increase the number of intermediate layers, which is Triple insulating glass. The heat transfer coefficient of Triple insulating glass can be as low as 0.6W/㎡· K (5Lowe+16Ar+5Clear+16Ar+5Lowe), But an additional piece of glass is needed, with a thickness approaching 50mm. The increase in thickness and weight not only means an increase in the cost of glass, window frames, transportation and installation, but also limits application scenarios, such as the renovation of old windows in modern buildings and historical buildings, which cannot use such thick glass.

Better coating glass

One or more pcs coating glass,with better emission rate

More insulating layers

More insulating layers with 12~16mm

Then, we will find that we have encountered a bottleneck. The way to break through is to increase the number of intermediate layers, which is Triple insulating glass. The heat transfer coefficient of Triple insulating glass can be as low as 0.6W/㎡· K (5Lowe+16Ar+5Clear+16Ar+5Lowe), But an additional piece of glass is needed, with a thickness approaching 50mm. The increase in thickness and weight not only means an increase in the cost of glass, window frames, transportation and installation, but also limits application scenarios, such as the renovation of old windows in modern buildings and historical buildings, which cannot use such thick glass.What kind of glass is needed in renovation of old windows?

Vacuum Glass is the only way

Then, how can we break through this bottleneck and continue to increase the number of glass and air layers?

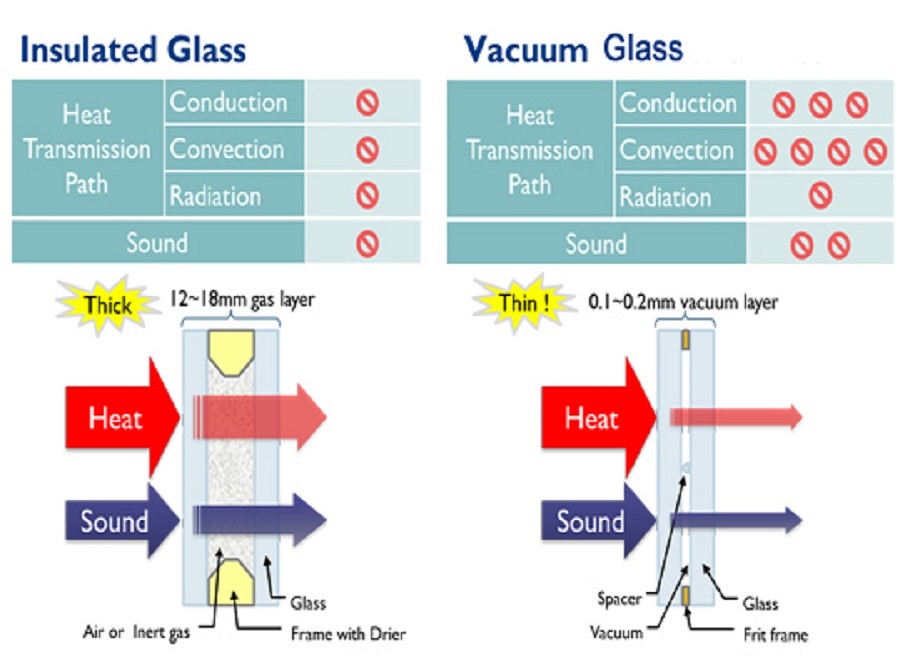

Fortunately, vacuum glass has been invented, that based on the principles of thermos bottles and vacuum fluorescent display technology, and gives us a better choice by using a vacuum layer instead of an air layer.

The magic of vacuum is that its thermal conductivity is related to the degree of vacuum, but not to the thickness of the vacuum layer. We can see that even if the thickness of the vacuum layer of vacuum glass is only 0.15mm, as long as the vacuum degree is good enough, it can achieve extremely low heat transfer coefficient. For example, V-i-G (3Lowe+0.15V+3Clear) with a total thickness only 6mm can have a heat transfer coefficient of 0.5W/㎡· K, and has even better sound insulation performance (36dB) than Triple IG

It can be said that the charm of vacuum technology has achieved vacuum glass, allowing us to break through the limit of Triple IG with only 2/3 of weight and 1/8 of thickness. The Triple IG has to add another piece of glass and an air layer to reach this limit.